Achieving your perfect brochure design isn’t just about attractive, colourful page layouts, sharp high resolution images and clean crisp typography. While the subject material and content information will be your focus of attention, specifying special print finishes for your brochure to achieve the best outcome is a worthwhile exercise when considering your desired objectives.

Selecting the correct print processes, materials and special print finishes will not only enhance the design of your pages but also make the experience of reading your literature a lot more memorable. Often its purpose is to make your business offering much more desirable. It can be the difference between something beautifully exquisite and engaging or simply uninspiring and boring.

Need Help with Brochure Design & Production for Your Business?

Professional brochure designers ready to discuss your brief > Request a Quote Now

Choosing special print finishes that are right for your brochure

When selecting special print finishes the aim is to make your literature more highly appealing, give your products and services added desirability and make your business stand apart from your competitors. The combination of how the materials feel to the touch and the overall appearance must work together to enhance the communication process.

When combining materials and finishes choose those that complement one another. Do not try to complicate your design with over-elaborate enhancements that detract from your core style. Often it’s best to keep your specification simple. For example, choose one material type and one contrasting finish; a nice uncoated board base material and apply your logo or text in metallic foil.

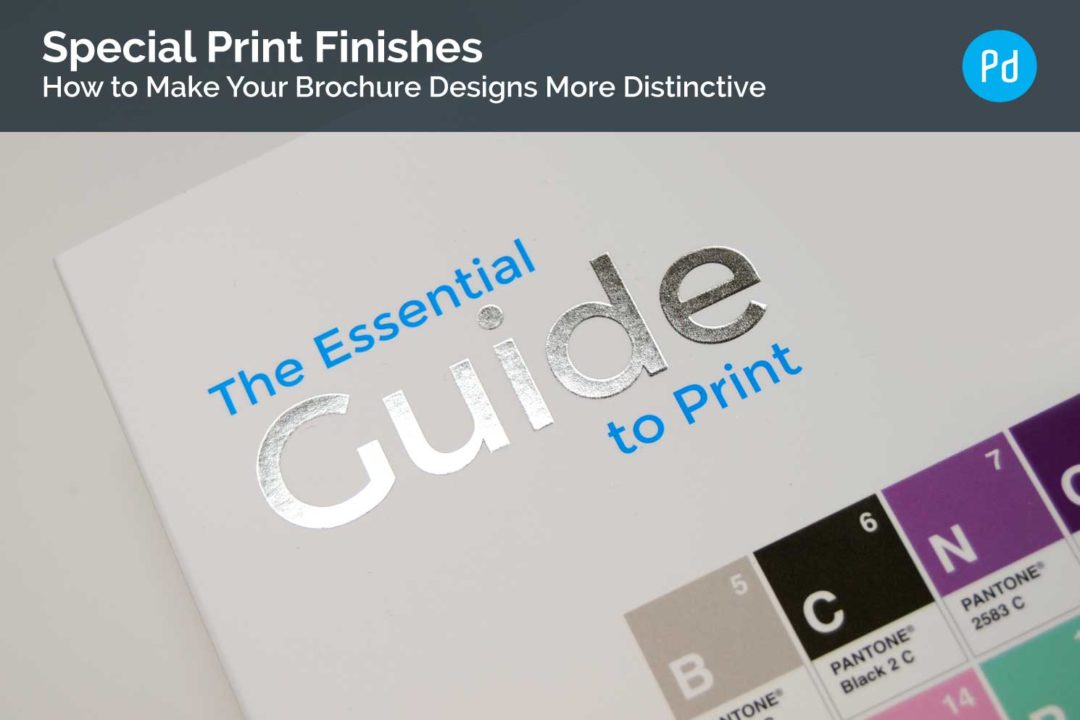

An experienced graphic designer who specialises in print design, will have sound knowledge of special print finishes and production methods which are achievable. As a print specialist they will be able to advise you creatively on the most appropriate specification and material finish for your brochure to achieve your desired effects. Find out more about the Essential Guide to Print produced by Palmiero Design for Belmont Press.

Choose from a number of special materials and design finishes which will give your literature that extra stand-out appeal to attract your target audience.

Printable Materials

Select the best paper stock for printing to match the special print finish effect you’re after. Each have individual characteristics and are available in a variety of colours and weight (thickness).

- Coated papers have a smooth surface finish that give much sharper image reproduction and enhances colour definition;

– Gloss: shiny, glazed looking surface

– Silk: smooth with lustrous velvety feel

– Matt: without shine, non-glare properties - Uncoated papers are a more porous material which absorb ink into their fibres more readily resulting in much softer image reproduction;

– Laid paper: textured surface

– Wove paper: flat, uniform surface - Special Stocks

– Duplex, Triplex and Quadplex boards: two, three or four different coloured sheets bonded together

– Pearlescent papers: a very unique paper with an elegant shimmering glimmer

– Synthetic materials: contain no wood pulp or natural fibres

Laminating

Laminating is great way to both enhance the visual appearance and also give added strength and durability to the surface of printed materials. Ultra thin plastic film (laminate) is applied to cover the entire surface of a printed sheet of paper or board. The most common lamination types in printing are:

- Gloss Lamination: glazed looking surface

- Matt Lamination: flat surface without shine

- Soft Touch Lamination: more luxurious velvet finish

- Holographic Lamination: Oriented polypropylene based, used for decorative purposes

Spot UV Varnishing

UV varnishing can be applied as a coating to a specific area on your print work to make it very shiny. It can be any size or shape. For example you can apply a UV varnish to your logo, over typography or over photo images to enhance and draw more attention to that area of print. The results can be very striking especially when the varnished areas catch the light, intensifying the contrast with the background material. Gloss UV varnishes work especially well when applied over matt or soft touch lamination.

Foil Stamping

Foiling is the process of transferring a metallic or pigmented foil onto a solid surface by applying pressure using an engraved heated die. Foils are available in a variety of colours and finishes, including silver, copper, gold and pearlescent. These are typically used to print logos and stylised typography on prestigious brochures, stationery items and product packaging. Foil stamping looks its best when applied to uncoated papers and boards or on matt or soft touch laminated surfaces. Also, holographic foils are used commonly as an anti-counterfeiting feature on documents such as certificates and vouchers.

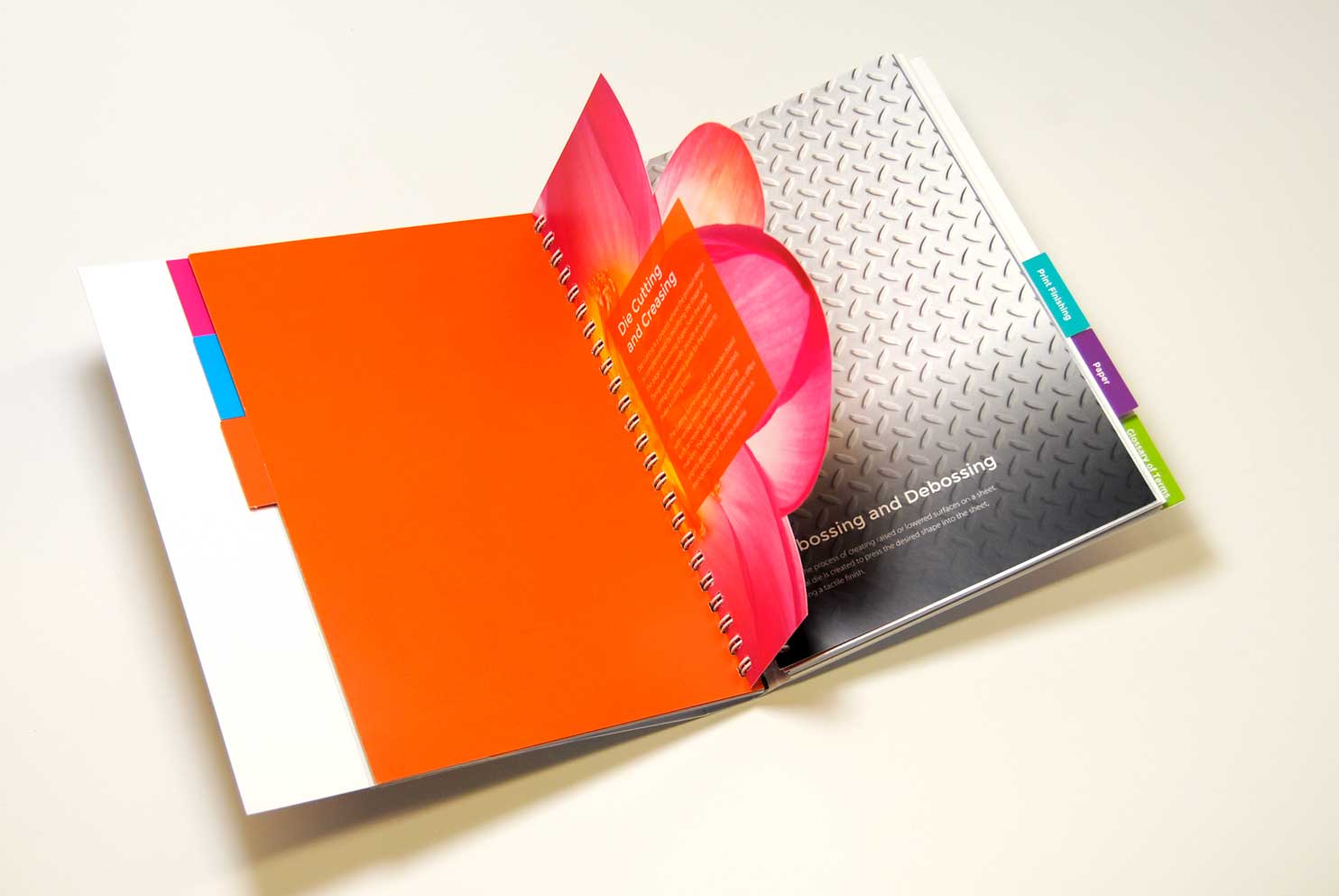

Embossing (Blind Embossing) and Debossing

This is the process of changing the dimensional appearance of a flat sheet of paper or board by applying pressure on both sides by using two metal dies made to a desired shape – one with a raised shape and the other with a matching but recessed shape. No ink or foil is used to highlight the embossed area.

– Embossing (or Blind Embossing): where the shape is pressed outward creating a raised surface

– Debossing: where the shape is pressed down creating an indent

Different embossing effects can be achieved depending on the type of die which is used:

– Flat: the result is much sharper edges

– Round: the result is curved extrusion surface

– Bevelled: allows for a deeper impression with sloping sides

– Sculptured: a carved image appearance with varying depths

Thermography

Thermographic printing uses heat to create raised profile line-work on a sheet of paper. This is achieved by applying powdered resin onto wet ink which is then exposed to controlled heat which fuses the resin onto the sheet. The result is a beautifully textured, raised profile, “orange-peel” effect with either a high gloss or matt finish. The most common uses for Thermographic printing is for stationery items such as letterheads, formal invitations, braille effect text, the printing of diploma certificates, etc.

Die-Cutting

Die-cutting is the process of slicing a flat material such as paper or card, into a specific shape using a die made from metal. This technique is used to cleanly cut out elaborate formations either to create open apertures or detailed shapes along the perimeter or border of the material. Used creatively it can be used to focus attention on the design of printed material by giving a distinct unique form or profile. Using this technique can also add practical functionality for items such as presentation folders. By using a combined cutting and creasing die a pocket or sleeve can be engineered easily from flat paper or card. Cutting dies are made from steel, making them durable which allows the process to be replicated accurately many, many times over.

Conclusion

- Special print finishes can enhance your literature to make it stand out from the crowd

- There are infinite finishing possibilities which are only limited by imagination and cost

- Can be expensive so decide which combination of special finishes best suit your objectives

- Always discuss your options with an experienced graphic designer who specialises in print design

- Consider alternative specification options and compare production costs carefully

- Talk to our expert brochure designers at Palmiero Design who can help you specify your perfect brochure for printing.

Looking for a way to make sure your designer knows exactly what you need from your brochure? Download our free guide for step-by-step tips and advice on creating the perfect brief for your designer.

Want to find out more about the services we offer at Palmiero Design? Feel free to get in touch or request a quote. We look forward to hearing from you!